Creo is a 3D CAD solution. It provides support in creating better products quickly by increasing the product innovation, replacing assumptions with facts, and repurposing the best designs. With Creo, you will go from the earliest stages of product design to an innovative, connected product. With cloud-based augmented reality in every Creo seat, you can collaborate with anyone, anywhere, at any time during the product development process.

Creo Simulation

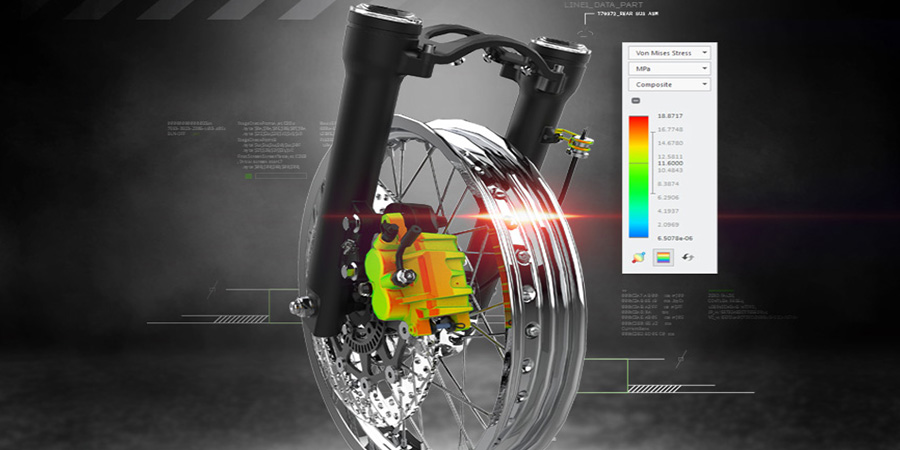

Simulate and analyze your product design to save money on physical prototyping while improving the longevity, reliability, and safety of your products.

It’s essential to your product development process to use digital prototypes to understand how your designs perform in real-world situations. Creo Simulation Live (Powered by Ansys) was created specifically for engineers. It includes solutions for structural, thermal, and vibration analysis, as well as a complete set of finite element analysis (FEA) capabilities. Before you make the first part, you can evaluate and verify the performance of your 3D virtual prototypes with Creo Simulation.

What is Creo Simulation Live?

Creo Simulation Live is a new feature in Creo 3D CAD software that allows engineers to simulate a parametric model in real-time. This means that every time you make a change in your model, you’ll see the results of the modelling environment right away.

More Simulations, Better Results

If the advantages of the instantaneous simulation aren’t clear, it’s explained how it could lead to better products in general.

We believe that because this is so simple, easy, and quick, consumers will be more likely to use simulation in the design process.

More simulations would yield higher-quality components that are more likely to meet their specifications.

As a result, design engineers can now optimize a design much more quickly. When the model is close enough, they no longer walk away.

Fluid Flow Simulation

CFD imitates the fluid (liquid or gas) over or around an object. Heat transfer, mixing, and unsteady and compressible flows, for example, can all be included in a single calculation. Without the use of a simulation tool, predicting the effect of such flows on your product’s performance can be difficult and costly.

Fluid Flow Simulation problems that have been solved in the past include:

- To determine a valve’s effectiveness, the pressure drop must be measured.

- To calculate thermal comfort factors, airflow inside a home or office environment is measured.

- Electronic thermal models are calculated using the temperature distribution of an electronic component.

- Lift and drag forces are calculated using an aerodynamic simulation.

If you need more information concerning Creo Simulation, Creo Simulation Live, and Fluid Flow Simulation, connect with CreoTek India right away!

Rajesh

Recently, I have been reading a lot about Creo Simulation and was able to find this blog. I must say this blog has been written by some professional. Grateful for your efforts!

Rajiv

Excellent reading experience! I got to know about Creo simulation and fluid flow simulation in detail here.